precise levelling may be required in certain instance in construction such as in deformation monitoring, the provision of precise height control for large engineering projects such as long-span bridges , dams and hydroelectric shemes and in mining subsidence measurments ,

for example , a dam that has been in place for many years is unlikely to be moving , However , should the dam fail the results would be catastrophic for thode on the downstream side . being under the pressure of water when full , the dam may be liable to distortion . The behavior of the dam must therefore be monitored. one way of monitoring any vertical movement along the dam is by levelling .

Since early warning of small movement is required ,

and since conclusions about movement must be made with statistical confidence , the leveling must be very precise .

There is more to precise leveling than precise levels . High quality equipment is very important , but so is the method by which it is used .

indeed the two components of precise leveling are precise equipment and precise procedures . Precise leveling uses the same principles as ordinary levelling but with :

(1) Higher quality instruments and more accurate staves

(2) More rigorous observing techniques

(3) Restricted climatic and environmental conditions

(4) Refined booking and reduction

(5) Least squares adjustment for a levelling net

precise invar staff

The precise levelling staff has its graduations precisely marked ( and checkedby laser interferometry) on invar srrips , which are attached to wooden or aluminium frames . The strip is rigidly fixed to the base of the staff and held in position by a spring - loaded tensioning device a the top . this arrangement provides support for the invar strip without restraining it in any way .

Usually there are two scales on each staff , offset from each other by a fixed amount ,The staff is placed upon a change plate at intermediate stations . A conventional levelling change plate is small and light and is designed to be unmoving on a hard surface . it is therefore heavy .

the feet are rounded so that they do not slowly sink or heave when placed on tarmac .The top is smooth . round and polished .

is made from a solid piece of steel and weighs about 10 kilograms .

for the most precise work , two staffs are used in which case they should be carefully matched in every detail . A circular bubble into the staff is essentail to ensure verticaly during observation . The staff should be supported by means of steadying poles or handles.

(1) the staff should have its circular bubble tested at frequent itervals using a plumb-bob .

(2) Warping of the staff can be detected by stretching a fine wire from end to end .

(3) Graduation and zero error can be counteracted by regular calibration .

(4) for the highest accuracy a field thermometer should measure the temperature of the strip in order to apply scale corrections .

instruments :

The instruments used should be precise levels of the highest accuracy . They should provide high-quality resolution with high magnification (×40) and be capable of being adjusted to remove any significant collimation .

This may be achieved with a highly sensitive tubular bubble with a large radius of curvature refined compensator would be necessary .

In either case a parallet plate micrometer , fitted in front of the object lens , would be used to obtain submillimeter resolution on the staff .

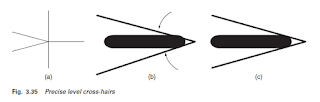

The instrument's cross-hairs , The distance that staff is away from the instrument's will affect which side of the cross-hairs is to be used . if the staff is far away use the normal horizontal hair, right-hand side of diagram . if the staff is close ,

the mark on the staff will appear too large to be bisected accurately . by comparing the two white wedges formed by the sloping cross-hairs and the mark on the staff , where the mark on staff is not correctly , where it is , a more precise setting of the micrometer can be made .

parallel plate micrometer :

for precise levelling , the estimation of 1 mm is not sufficiently accurate . A parallel plate glass micrometer in front of the object lens enables reading to be made direct to 0.1 mm , and estimated to 0,01 mm .

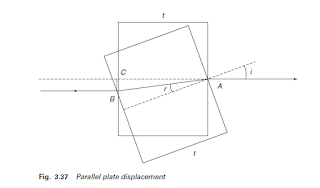

the parallet plate micrometer works by refracting the image of a staff gradutuin to make it coincident with the cross-hair , there is , therfore , no estimation of the position of the cross-hair with respect to the gradutin .

The principle of the attachment is seen , hard the parallet plate been vertical the line of sight would have passed through without deviation the micrometer the parallel plate is tilted until the line of sight is displaced to the nearest division marked on the staff , which is 1,02 m . The rotation of the micrometer drum is proportional to the displacement of the image of the staff , The amount of displacement s measured on the micrometer and added to the exact reading to give 1,02647 m , only the last decimal place is estimated .

That the plate could have been moved in the opposite dirction , displacing the line of sight up . since the parallel plate micrometer run is normally equal to the gap between two successive divisions on the staff it will not be possible to gain coincidence on more than one division .

The displacement is related to the rotation of the parallel plate as follows , the plate pivots about is t and the ray of light from the staff is refracted by an angle r , u is the refractive index of the glass of the plate .

Displacement = BC = AB sin (i - r )

0 تعليقات

اذا كنت خارج البلاد ومحتاج معلومة مهمة ومش لاقيها ! ممكن دلوقتي تكتب نوع المعلومة الي انت محتاجها وراح نجاوبك بيها علي طول من خلال اضافتها للموقع او من خلال الرد عليك من خلال بريدك الالكتروني او الاتصال بك مباشرة

(أطلب الشرح الي انت محتاجة ولا تتردد)

فريق منارة العلوم يساعدك علي مدار 24 ساعة